in Treviso with a small production’s unit wich expand itself during the time, up to the

actual 3000 mq where work around 40 people.

Since some years, Nastrificio, besides the Made in Italy, produces also in Romania and

it’s certificated ISO 9002 and SA 8000 above all.

The production, currently, also thanks to two thermo transfer patent, spaces from

thermo pairing to the laser cutting, from thermo adhesive

ribbons to the finished garments thermowelding.

Nastrificio realizes also in comnmercialized, garments wich are totally thermo

welded.

Futhermore, also thanks to the prototype department, Nastrificio is able to purpose to

its clients, always new ideas, supported by the technologic’s innovations.

Nastrificio di Signoressa realizes thermowelded garments, heat transfer, fabric’s pairing, laser cut, thermoadhesive ribbons and finished garment’s thermowelding.

we are able to execute pairings with thermoactivable films suitable for the different types of materials to go to meet the most several requests. We also provide to the film’s application on the reverse of the client’s fabric for then cutting it in oblique, ready for the next thermotaping phase. Futhermore we can pair fabric on fabric in roll to a max height of 160 cm. Pairing can also be execute in sheets.

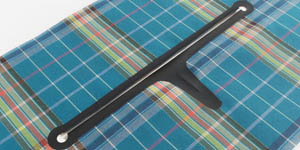

thermotaping is a technique that, with the heat application of a ribbon, allow to strenghthen and flatten stitching/seams or other types of union and to respect, from the inner part, the impearmeability of waterproof garments. it’s possible to use ribbons, evern colorful, in polyurethane and it’s futhermore possible to treat a fabric supplied by the client, make it thermoactivable and use it fot the taping. Taping gives also a great sense of cleanliness to the inner part of the garments and create an effect of order and elegance.

thermowelding is an innovative technology which substitutes the tradinional stitching to unite one fabric to the other, it remove thikness, keep unchanged the phisical features of the materials and improves the machanic ones. The thermowelding tecnique’s is able to respect the own features of the fabrics, mantaining softness and elasticity.

the lavorations executed in calender, are realized besides to the pairing of fabrics. It can be executed continuously even with more ribbons, placed one next to the other and it’s also helpful for delicates fabrics and/or particular materials that prefer delicate tempertures and pressure.

its a technology of fusion, used to substitute the traditional stitching. It’s used simultaneously to the cut of the fabrics, standing one near to the other, without any kind of overlap and/or double thinkness. ultrasound’s technology is possible on synthetic fabrics or fabrics with an high percentage of syntethic.

Laser technology allows to cut any synthetic fabric, melting in a controlled way the edges of the fabrics with an high precision and without direct contact, avoiding so eventual deformations and with low graphic realization’s time. it’s possible to cut also natural fiber fabric’s, verifying the quality of the cut step by step, in way to avoid any trace of “burning” more or less visible.

SPECIAL LAVORATIONS: laser cut together to thermowelding. ACCESSORIES: application of accessories in thermowelding. Realization of frames and profiles. RELIEFES: pairing’s technique of different fabrics. INSERTS: realized using several techniques and laser machines, plotter and pairing. LABELS: labels realized on different polyurethane bases thermoadhesive or not.

Nastrificio di Signoressa supplies ribbons for clothing.

TNT THERMOADHESIVE – POLYURETHANE – REFLECTIVE – PAIRED – SATIN – COTTON

In particular: thermoadhesive, polyurethane, thermoactivable films, thermoadhesive tnt and not, paired,

lining.

Are executed the following different kinds of cut: laser, ultrasounds, plotter, straight grain, sloping, shaped.

PROFILES - TUBE – PLEATED – PIPING – SOURMOUNT – BRAIDS

Among our lavorations we also include the ribbon’s cut from the fabric roll to straight grain, oblique and shaped. Our range include futhermore: ptofiles assembled in stitching or thermowelded, pleated with one or two central stitching, folded up, stitched piping or welded by ultrasounds.

Signoressa di Trevignano

Via Treviso, 109 | TREVISO | Italy

Tel. +39 0423 677157 | Fax. +39 0423 677143

AMMINISTRAZIONE

@nastrificiodisignoressa.com

DIREZIONE

@nastrificiodisignoressa.com

P.IVA 03932740263